Patz

Patz 3333 Manure Pump

The Patz Model 3333 Multi-Use Vertical Pump provides high performance for quick transfer of liquid wastes including:

-Dairy waste water

-Manure separator liquid residues

-Hog manure

-Rain or flood water

- The tapered-bore drive pulley mounts to a 1-1/8-inch (29 mm) drive shaft with a greaseable flange bearing at the top of the drive tube. A lip seal below this bearing keeps contaminants out of the drive tube. The drive tube is filled with oil to lubricate the support bearings inside the tube and the bottom bearing.

- Easy access to oil reservoir. End guessing - inspect oil level conveniently in transparent oil line at top of pump. A large fill hole allows easy access for adding oil to the drive tube. Patz recommends using a non-detergent oil.

- High-volume delivery. The voluted design of the impeller housing and the curved blades increase pumping efficiency at a rate of around 500 gallons per minute.

- Lower repair costs with abrasion-resistant steel impeller housing and shredder plate.

- Protection against bearing contamination. The lower bearing's oil-bath chamber has four seals to keep contaminants out.

- Bearing seals can be purged every 8 hours thanks to a grease line from the seal pack to the top of the pump.

- Clogging prevented and positive input provided. Shear plate located close to the impeller to help prevent clogging and provide positive input.

- Shear plate has two legs to help support pump off the floor of the pit.

- Impeller transition area features beefed-up steel for long life.

- Light weight and high-strength discharge pipe. Our 3-inch (76 mm) diameter Schedule 80 PVC discharge pipe reduces the weight of the pump for easy handling while providing a high-strength, low-wear, low-friction discharge tube. Various lengths available from 3 to 12 feet.

- All stainless steel hardware below the liquid line for long life and easy servicing.

- Attaching eye located on top of the pump allows easy insertion and removal of the unit in the pit with a tractor loader, skid-steer loader or winch.

- A steel plate is included as standard equipment to allow you to precisely position the pump to match your pit depth. Plate can be lagged to a concrete pad or curb.

- Pump available in various lengths to fit pit depths of 3 to 12 feet (1 to 3.6 m).

Patz 4444 Manure Pump

This versatile pump handles limited fibrous waste. The impeller blades' swept-back design increases pumping efficiency for high-volume flow through the 4-inch (101.6 mm) steel tube.

- Pumping capacity up to 1,580 gals./min (5,981 liters/min.).

- Available in lengths to fit your application: 6 ft. (1.8 m), 8 ft. (2.4 m), 10 ft. (3.0 m), and 12 ft. (3.6 m)

- A 16-inch (40.6 cm) Impeller for added capacity.

- Variable agitation capacities with a standard dual agitation system.

- Abrasion-resistant steel in high wear areas for longer life.

- Versatile - can be used in a variety of applications: Agitate a pit, Move from short-term to long-term storage, Load tankers/spreaders and separators, Transfer wastewater

- Tapered-bore drive pulley mounts to a 1-3/4 inch (44.5 mm) drive shaft with a greaseable flange bearing at the top of the drive tube.

- Easy access to oil reservoir. End guessing! Inspect oil level conveniently in transparent oil line at top of pump. A large fill hole allows easy access for adding oil to the drive tube. Patz recommends using a non-detergent oil.

- High-volume delivery. The voluted design of the impeller housing and the curved blades increase pumping efficiency.

- Protection against bearing contamination. The lower bearing's oil-bath chamber has 3 seals to keep contaminants out. No sleeve bearings to wear out fast.

- Clogging prevented and positive input provided. Shear plate located close to the impeller to help prevent clogging and provide positive input.

- Lifting loops located on top of the pump allows easy insertion and removal of the unit from the pit with a tractor loader, skid-steer loader or winch.

- A steel mounting plate is included as standard equipment to allow precise positioning of the pump to match the pit depth. Plate can be lagged to a concrete pad or curb.

- Pump available in various lengths to fit pit depths of 5 ft. 6 in. (1.7 m) to 12 ft 10 in. (3.9 m).

Patz 6000/8000 Manure Pump

Easily insert pump into pit because it is articulated on two-point hitch. Enjoy the convenience of all-hydraulic controls or choose manual controls. The loading pipe is 20 feet long (6.1 m) and includes a wheeled undercarriage.

- PTO: 540 or 1,000 RPM

- Impeller: 20 in. x 4 in. (508 x 102 mm), curved blades

- Agitator nozzle: Flexes 5° above to 35° below horizontal

- Valve Style: Knife

- Valve Functionality: Shift at idle speed

- Loading Pipe: 20 ft. (6.1 m) pipe with wheeled carriage

- Match your pit depth with choice of four pump lengths: 6, 8, 10 and 12 feet (1.83, 2.44, 3.05 and 3.66 m). Large U-bolts allow the frame to be adjusted up or down for precise placement.

- Match your desired speed of transfer and loading with two pump sizes: 6-inch (152 mm) and 8-inch (203 mm) pipe.

- Reduce agitation time with dual nozzles that blend crusted manure and settled solids into a liquid slurry fast.

- Get better pit clean out by agitating every corner with adjustable nozzles (rotate both horizontally and vertically).

- Remove clumps of straw with chopping action over impeller shredder plate.

- When there is no crusting or settled solids, pump liquid manure with low-investment pump. Or, add options as needed.

- Save time when agitating, transferring, and loading due to swept-back impeller blades for high-volume pumping [up to 3,500 gallons (13,247 liters) per minute].

- Choose from two pump mounting options for agitating below-ground liquid-manure storage pit and for loading liquid-manure spreaders: Stationary base secured to manure pit or Two-point tractor hitch with hydraulics for tilting (540 or 1,000 RPM).

Patz 6000E Manure Pump

- A stationary base secured to manure pit is standard on the 6000E Pump.

- Equipped with a two-point tractor hitch for easy insertion and removal from pit for service.

- Match your pit depth with choice of four pump lengths: 6, 8, 10 and 12 feet (1.83, 2.44, 3.05 and 3.66 m). Large U-bolts allow the frame to be adjusted up or down for precise placement.

- Twin motor belt drive systems are easier on the upper drive shaft and bearings.

- Get better pit clean-out by agitating with a nozzle which can be rotated horizontally.

- Remove clumps of straw with chopping action over impeller shredder plate.

- When there is no crusting or settled solids, pump liquid manure with low-investment pump or add options as needed.

- Save time when agitating, transferring, and loading due to swept-back impeller blades for high-volume pumping up to 2,500 gallons (9,463 liters) per minute-during agitation and 2200 gallons (8,328 liters) per minute during loading.

- Get high load-carrying capacity and long service life from tapered roller bearings in oil bath chamber protected by three seals.

- Unique plumbing system eliminates need to enter pit. Ask dealer for details.

- Lower repair costs with impeller housing of abrasion-resistant steel in high-wear areas.

- End guessing about oil level. Inspect oil level conveniently in transparent oil line at top of pump.

- Horsepower Requirements: Twin 15, 20, 25, or 30 HP, 3-phase motors.

- Ask for more information about remote agitation/storage systems.

Patz 9000 Manure Pump

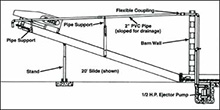

The operating principle is simple. The gutter cleaner moves manure over a screen. Liquids drop through the screen into the sump that is installed below the floor of the gutter.

The submersible pump moves the liquid through a 2-inch PVC pipe to a discharge point at the end of the slide into your manure spreader. The gutter cleaner takes the solids up the slide and discharges them into the spreader. The system uses no check valves. When the pump is turned off, liquids will flow out the sloping pipe or drain back into the sump.

Maintenance is low. The pump is heavy duty with an oil bath motor. It uses 230 volts, the same as the gutter cleaner but the motor draws less than 6 amps.

To eliminate corrosion, the system has a pump with stainless steel parts and utilizes PVC piping that won't rust.

Should the pump need service, it lifts out easily. If the pump is out for service, you can still operate the gutter cleaner.

The Patz Liquid Transfer System does not require extra space in your barn. It can work with all brands of gutter cleaners.

The pump's two-inch discharge matches the intake diameter for full flow. Also, they use two-vane, nonclogging impellers.

The system is easy to install anytime - winter or summer. Your system is ready to use the day after installation.

So, if you have a problem with manure rollback on your gutter cleaner slide, your Patz Dealer has the solution - the Patz Liquid Transfer Systems.

- Pump Performance: G.P.M. at total head in feet, Subtract 2-1/2 feet (76.2 cm) of head per 90° elbow.

- 5'(1.524m) - 160

- 10'(3.048m) - 130

- 15'(4.572m) - 80

- 20'(6.096m) - 60

- 25'(7.620m) - Shutoff

- Gutter Widths: 15" to 20" (381 mm to 508mm)

- Hole Size for Installation: 18" (457 mm) wide x 24" (610 mm) long x 30" (762 mm) depth below gutter bottom (20 gal. sump).

- Pipe Size: 2" (50.8 mm) PVC schedule 40 Pipe supports should be every 10' (3m) apart.

- Pump Dimensions:

- Height to top of handle: 19-3/8" (492 mm)

- Width at widest point: 12-5/8" (321 mm)

- Discharge: 2 NPT

- Suction inlet opening: 2" (51mm)

- Weight: 84 lb. (38 kg)